Manufacturing

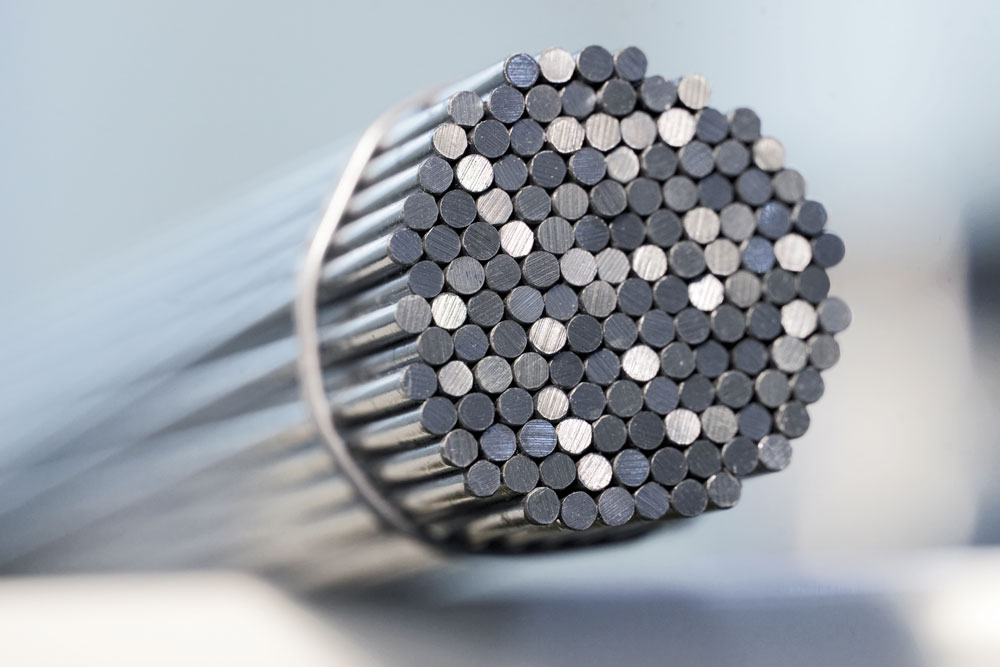

We have an exclusive partnership with a ball manufacturing plant, which is one of the few in the UK that can produce balls fully in-house. All of the raw material used in the factory is sourced from either Europe or the USA and full material certification is available upon request.

Heading

Using high-speed automatic machines, raw material (in the form of wire or bar) is formed into spherical blanks.

This stage helps obtain accurate blanks which have a positive effect on subsequent stages of the production. In order to ensure accuracy of form, these blanks are measured at regular intervals.

Flashing

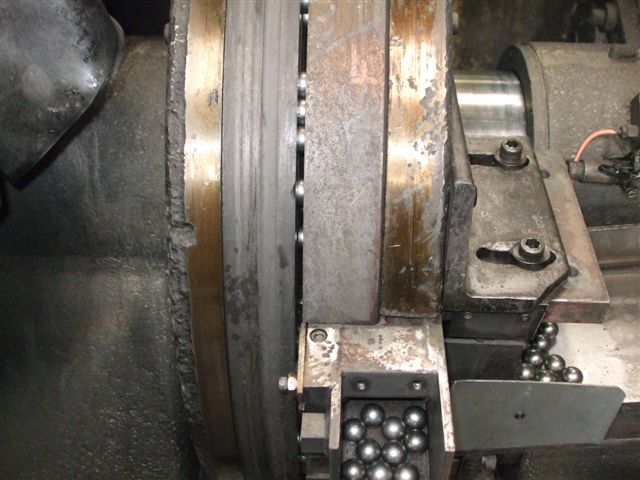

Headed blanks are then roughly ground during rotation under high pressure, in grinding plates manufactured from special cast iron - this removes the flash as well as any large surface defects and excess material. The balls are repeatedly fed into the grooves for grinding.

Measurements are regularly taken at this stage in order to monitor the removal of material and the resulting size and form of the ball.

Heat Treatment

Depending on the material used, the balls are tempered in a fully controlled rotary furnace. This process relieves any built-in stresses created during the previous stages of manufacture and gives maximum strength and durability to the balls.

Certain materials such as Chrome Steel, Stainless Steel and Carbon Steel require heat treatment to achieve a certain hardness or to relieve any stress that has been imparted into the material during the manufacturing process. Other materials, like Monel K-500 and AISI M2 Tool Steel, require heat treatment to allow them to soften and be formed into balls.

Alternatively, this process can also be used to distress the product in the event that a rough surface finish is required - for example, if the product is going to be used in a cleaning/burnishing process.

(Not all materials are heat-treated)

Grinding

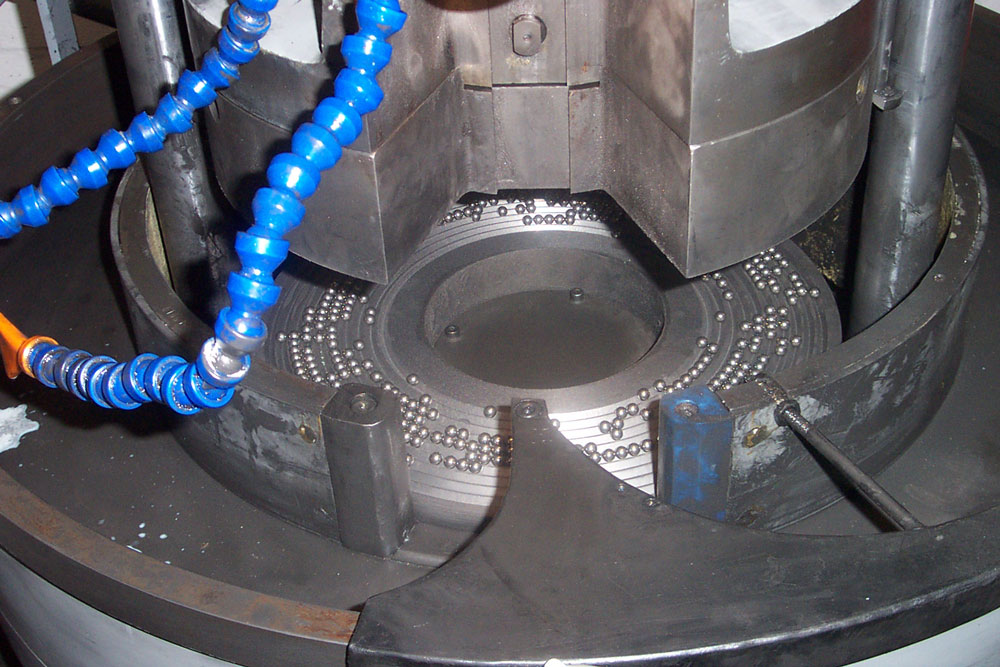

This process is carried out to remove any oxides produced as a result of the heat treatment process, simultaneously improving the spherical form of the ball. In order to achieve this, the balls are ground between a rotating grinding wheel and a stationary cast iron plate.

Measurements are regularly taken in order to monitor the removal of material and the resulting size and form of the ball.

Lapping / Polishing

The hard ground balls are then lapped to achieve their final dimensional form and surface finish. This is carried out between cast iron plates, one rotating, and the other stationary. The pressure exerted on the grinding plate is crucial to this process and so it is constantly monitored.

Measurements are regularly taken in order to establish the correct pull point. If an improved surface finish or polish is required, the balls may be placed into a vibratory polishing machine with various polishing media.

Final Inspection

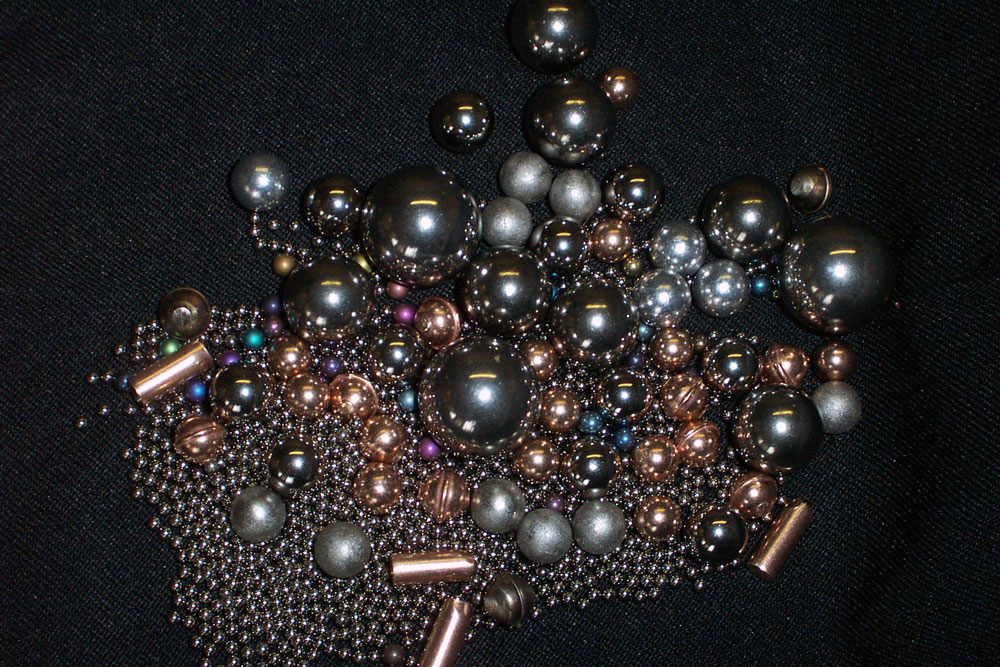

Following completion of the manufacturing process, the balls undergo a final quality inspection, where various characteristics are measured depending on the grade of ball and the customer’s requirements.

Typical characteristics that we measure are size, tolerance, roundness, hardness and surface finish.

Packing

This is the final stage of the process, involving the weighing of the product into the required quantities and the subsequent bagging and packing.

All products are packed taking into account the size, physical properties of the material and the grade of ball - packing will differ in order to prevent any damage or corrosion of the product. Each box is labelled with a full description of the product, including a unique batch number that is used for traceability back through the processes right to the raw material. Our labelling can be tailored to the specific requirements of the customer.